LG Energy Solution Wrocław receives Q1 certification from Ford. This is the gold standard

LG Energy Solution Wrocław focuses on quality and innovation. It pays off, because the Wrocław plant has been awarded the Q1 certificate by Ford Motor Company – the gold standard in the automotive industry. See how the company ensures quality at its Wrocław plant. We present the Quality Experience Room and the world's only Test & Validation Lab.

“This prestigious certificate, whose name means ‘Quality is No. 1’, is awarded only to those suppliers who consistently meet the highest standards in terms of quality, systems, guarantees, and deliveries. It is widely recognized as the gold standard of quality in the automotive industry,” says Korean LG Energy Solution Wrocław.

The company earned the certification after successfully meeting the requirements in all evaluation categories as part of Ford's rigorous verification process. “This achievement reflects the company's knowledge and experience in quality control, continuous improvement, and commitment to customer service,” says the Korean company.

Quality Experience Room. LG Energy Solution Wrocław focuses on quality and innovation

Company representatives emphasize that quality standards at the Wrocław-based lithium-ion battery manufacturing plant are not only discussed during audits or awards.

In a special room at the LG Energy Solution Wrocław plant, experts conduct training on the quality of the company's products.

Entire groups of change leaders are trained in various languages – Polish, English, and Ukrainian. The Quality Experience Room has several demonstration stations showing different types of defects that can occur on the production line.

Our mission is to raise awareness and consolidate employees' knowledge of the safety and quality of our products. In this work, the smallest detail is of great importance, and overlooking it can have equally serious consequences – for the business and for user safety.

Tomasz Dumicz, director of the module production department at LG Energy Solution Wrocław and initiator of the Experience Room at LG Energy Solution.

The training stations are an accurate representation of specific stages of the line in designated LG Energy Solution Wrocław projects, marked with customer names. While training, employees can test their perceptiveness and knowledge of LG products.

Operators are trained for several days to achieve independence in working at a specific station. LG Energy Solution Wrocław employees often have so-called multiskills, meaning they work at several or a dozen or so stations. Achieving full competence is time-consuming, and even after completing the training, employees are required to repeat the educational path in the Quality Experience Room every six months.

During training and daily work, we remind our employees of the importance of proper workplace organization. Standardization is not just a procedure, but a guarantee that the task will be performed efficiently and correctly. This is particularly important in production plants.

Kamila Gościniak-Wronkowska, Module Line Improvement Team Manager at LG Energy Solution Wrocław.

Test & Validation Lab – what tests does LG Energy Solution Wrocław perform?

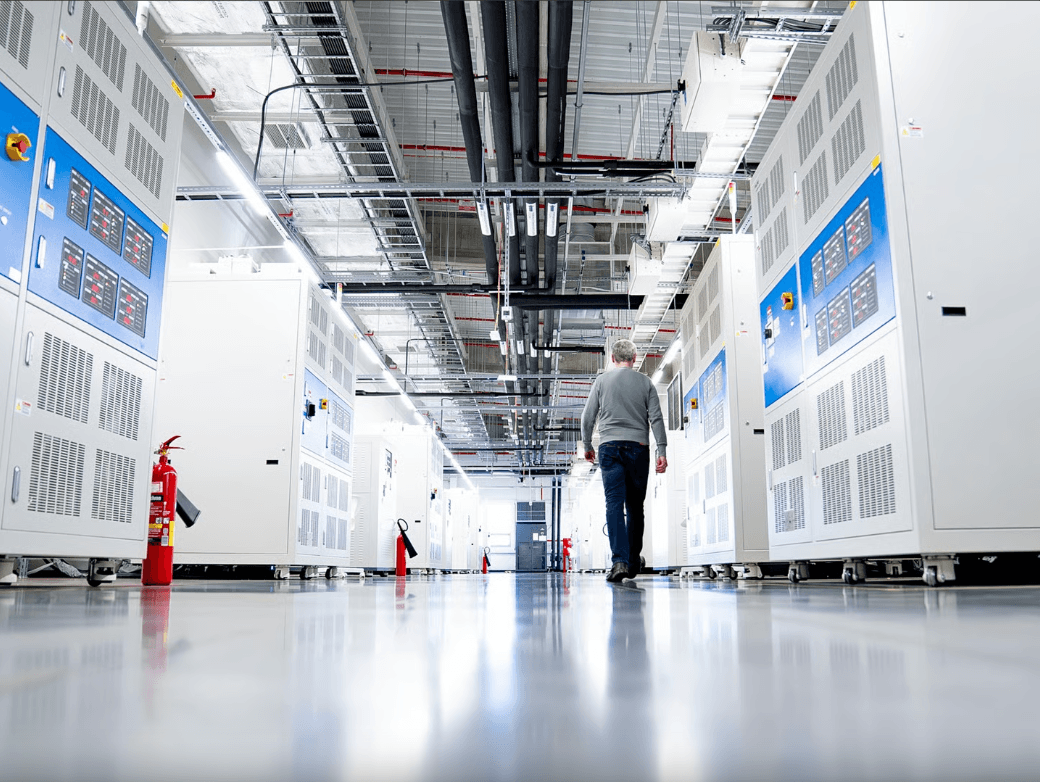

The Test & Validation Laboratory at LG Energy Solution Wrocław is a specialized unit where battery components and finished products undergo rigorous testing to confirm that they meet the highest standards of quality, safety, and performance.

The laboratory plays a key role in verifying the durability, efficiency, and reliability of lithium-ion batteries through a wide range of mechanical, electrical, and environmental tests.

- It supports both product development and mass production, enabling early detection of potential problems and validation of improvements before they are implemented.

- By combining advanced equipment with expert knowledge, the laboratory drives continuous innovation and reinforces LG's commitment to providing safe and highly efficient energy solutions.

Jangha Lee, president of LG Energy Solution Wrocław, emphasizes that it is not only advanced machines and equipment, but above all the experience and engineering skills of the employees that make up this laboratory.

Very often, these are people who have been working with us since the beginning of battery production near Wrocław. Building such cultural capital by supporting education: training and developing experts within the organization or cooperating with the best universities in the country is one of our local content goals. It is also one of our strongest cards in the conversation about what LG Energy Solution Wrocław gives to Poland.

Jangha Lee, President of LG Energy Solution Wrocław.

Test & Validation Lab - the only laboratory of its kind in the world is at LG Energy Solution Wrocław

Test & Validation Lab is the only laboratory of its kind in the world among all the Group's branches, with the most comprehensive ISO 17025 certification, which is awarded to research laboratories with the highest level of research and calibration competence.

Rafał Grosner, Test & Validation Operations Manager at LG Energy Solution Wrocław: "We perform many types of tests on batteries: performance, safety, and environmental tests. In terms of safety and environmental tests, these include short-circuit, nail penetration, crushing, overcharging, drop, shock, vibration, pressure, and climate tests.

To carry them out, we have very specific rooms with a height of 9 meters, made entirely of reinforced concrete, with resistant double doors, full monitoring, and control over the test being performed.

Rafał Grosner, Test & Validation Operations Manager at LG Energy Solution Wrocław.

“All this is to ensure the highest quality of the tests/research carried out and, consequently, to make sure that the product released for mass production and ultimately to the customer meets the most stringent global standards,” adds Rafał Grosner.

LG Energy Solution Wrocław - the largest electric car battery manufacturing plant in Europe

LG Energy Solution is a global leader in providing advanced lithium-ion batteries for electric vehicles (EVs), IT products, power tools, and energy storage systems (ESS).

The company, originally named LG Chem Wrocław Energy, began operations in 2016. It is the first and largest electric vehicle battery production center in Europe.

- In 2021, LG Chem Wrocław Energy was transformed into LG Energy Solution Wrocław – the new name of the plant reflects changes in the structure of the Korean conglomerate.

- In 2025, LG Energy Solution announced that its production plant in Wrocław was launching production lines for ESS (energy storage) systems.

- In March 2025, we reported that LG Energy Solution Wrocław would build one of the largest electricity storage facilities in Europe.

- Electric cars from automotive giants such as Audi, BMW, Fiat, Ford, Porsche, and Volkswagen are powered by batteries manufactured in the Wrocław agglomeration.

- LG Energy Solution Wrocław is located in a 100-hectare modern technology park, which employs several thousand people.

The greenfield investment in Wrocław has resulted in the introduction of state-of-the-art technology to Poland and has made our country a European leader in this industry.

The company produces 700,000 EV batteries per year, and its goal is to produce one million batteries for electric cars per year.