Ryanair's cool offer: jobs for 100 engineers starting immediately. No experience necessary

Ryanair wants to hire up to 100 engineers in Wroclaw. It is looking for aviation specialists and beginners with no experience in the industry, offering them training. "No previous experience is required. Our Engineering Academy provides specialized training to equip candidates with the necessary skills to quickly embark on their career path," says Ryanair.

The carrier encourages applicants: “Whether you are an experienced engineer or just starting your career at our training academy, this could be the perfect career path for you.”

Are you suited to aircraft maintenance?

– Ryanair is expanding its team of engineers in Wroclaw and is currently hiring both experienced aircraft engineers and those who want to start their career in aviation. Our base in Wroclaw offers the opportunity to gain practical technical skills and build a rewarding career," says Alicja Wójcik-Gołębiowska, Head of Comms CEE & Baltics at Ryanair.

You can apply via the Ryanair website. What requirements must applicants meet? Information can be found on the website of the future potential employer.

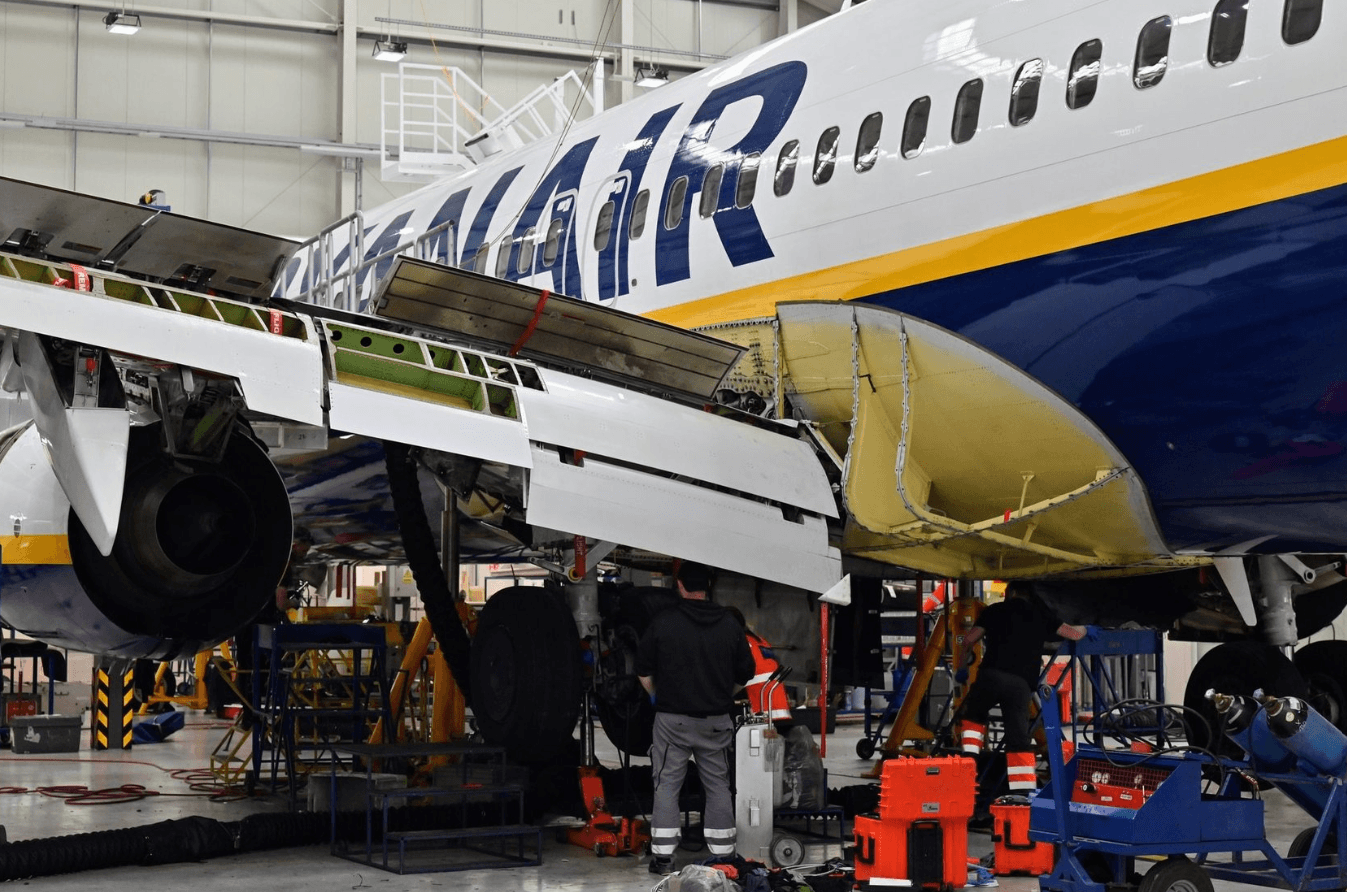

What does Ryanair do at its Wroclaw base?

Every aircraft must undergo inspections. Their frequency is determined by the manufacturer. Three factors are key: the age of the aircraft, the number of hours flown, and the number of takeoffs and landings. Inspections vary from short ones lasting a few days to 23-day inspections.

From a safety point of view, it does not matter whether we are flying on an aircraft manufactured in 2025 or 2005. The older aircraft must have undergone all inspections and any worn parts must have been replaced.

An aircraft that does not have documents certifying that it has undergone an inspection in a timely manner will not be allowed to fly. And it will not have these documents if all components that require inspection are not checked and replaced during the inspection.

What tasks will be performed while working at the Ryanair base?

Aircraft maintenance is a specific and highly codified process. There are procedures that result from regulations applicable to all airlines and internal rules.

Every part, even the smallest screw, is recorded and, after removal, has its place on one of the shelves. It is noted who removed it and who installed it, and no parts that have not been approved by the aircraft manufacturer are installed.

Everyone's work is monitored. Even those who monitor are monitored. Finally, everything is approved by a supervisor certified by the Civil Aviation Authority.

Take an aircraft mechanic, for example. There is a trainee mechanic who works under supervision. Higher up in the hierarchy is a second-class mechanic, who is also supervised. A first-class mechanic works independently, but this does not mean that their work is not checked.

Above him is an assistant mechanic. However, even he is not at the top of the hierarchy, as there are still mechanics licensed by the Civil Aviation Authority who ensure that everything runs according to procedure. The work of the entire team is approved by a supervisor. Without his consent, the aircraft will not return to the runway.

The removal and installation of each part is described and signed by several people, in accordance with the hierarchy. Who replaced it and why. Tools are also recorded, each has its own place where it is returned after use.